Content Type MD [mark-down]

Stud weld chucks video.

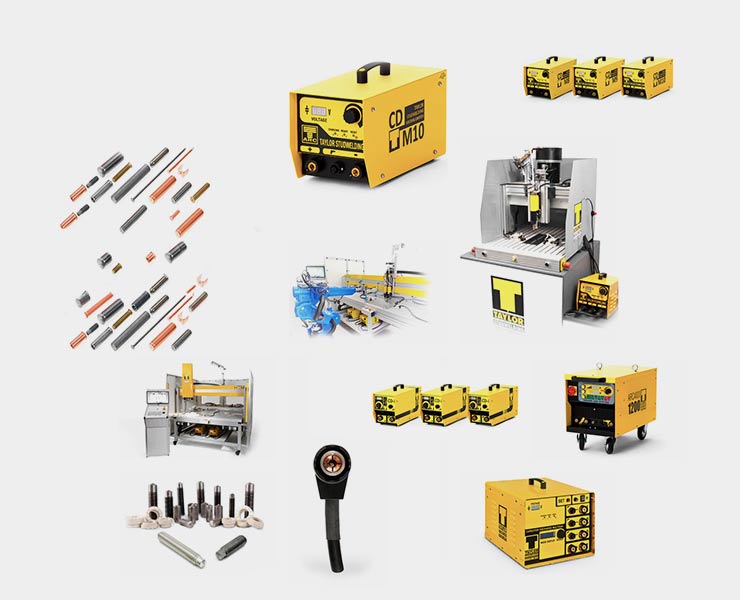

Welcome to Studfast studwelding CD chucks video. Today, we're going to be talking about capacitor discharged chucks and the different types and different names that people have for them. At Studfast Studwelding, we are a leading UK supplier of CD collets and chucks. You may hear several different terms to describe the same CD chuck. They can often be referred to as a stud holder, arbour, chuck or collet. These are all the same name for the same item used in studwelding process. The CD mandrill is used to hold the stud within your CD studwelding handtool.

Below includes all the terms used to describe a chuck. Collet is a common one and it's chucks you'll hear mostly. Chucks are the most common used terms, but you might also hear:

- Mandrills

- Collars

- Arbours

- Stud Holder

- Discharge collars

- CD Chuck

- Chuck Collet

- Chuck CD

Arbors is another one that we hear, and some people just call them stud holders, so they all refer to CD Chuck's. They all refer to the same item. There is no universal term for Chuck's that are used in the capacitor discharge stud welding process.

At first, if you're new to the process, it may be a little daunting, you know, with all the choice or the choice of sizes. It might seem like a difficult choice at first. So all you need to do is speak to one of our team and within minutes we'll point you in the right direction.

Which chuck is right for your application?

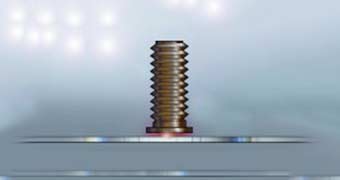

Which accessory? Which chuck is right for your application? The most commonly used term is Chuck, mandrill, however you like to describe it, are these copper collets.

For our CD machines that we sell, we use these copper chucks. They are the most commonly used in capacitor discharge studwelding. And so these ones that we are showing you, we supply them, we hold stock of from 2.5 up to 10. They're the main ones that you will see, you see the 8 and 9 10.

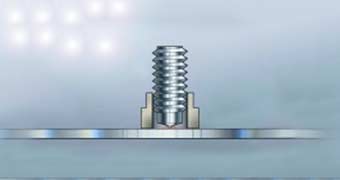

All contact capacitor discharge machine's mainly uses arbours or chucks of many different sizes. I've got a few here for you today. This is called an offset Chuck. So you might have seen our previous video on these. This fits into the end of your gun as a normal Chuck would here, and it lets you put studs down, you know, close to an upright or right into a corner.

Here we have an Earth tag Chuck. And again, same go into you in the end of the gun, like a normal Chuck straight in there. Tighten it up, Chuck normal. And these weld. So if you can see the little pep on the end there. Well, goes onto your sheet metal and then an Earth connector can go onto it. They're single. And there's also double tag that you can get. These copper cd arbors should use our CD machine. If used properly, they should last over 1,000 worlds and to make them last over 1,000 welds.

Take Advantage of our Offer on Chucks This Month

We're offering a staggering 20% off chucks. But you must register your interest now to lock in this deal for your company

People have different names... Collets is a common one, so it's chucks you'll hear mostly. Chucks are the most common used terms, but you might also hear:

- Mandrills

- Collars

- Arbours

- Stud Holder

- Discharge collars

- CD Chuck

- Chuck Collet

- Chuck CD

All these terms are used to describe the (usually soft copper) holder inside the hand tool, essential for maintaining good quality welds. We will explain how to keep good quality welds in the video below

Ok the crucial thing is to set up the Chuck correctly. Right? the best way to ensure good collet life is as follows. You have to have a 1 millimeter gap from the front of the mandrill to the back of the flange. The easiest way to set it up is to have the stud sticking all the way out. You back off the back stop. Press the third all the way in and then move it out. So you've got 1 millimeter . That will give you the correct protrusion and the correct spring pressure to ensure satisfactory world.

Now you'll notice the little rubber rings, the little rubber rings are there to keep the whole thing tight. If the weld collet or the cd chuck gets loose and the stud falls out, you're going to have a lot of issues with poor welds. This can happen when the operator removes the hand tool off the stud at an angle. What happens is. The lines on the collet, on the chuck open out and they stud becomes loose. What then happens is arcing will appear inside the collet. This is where you lose energy, you get a bad weld. And this will burn out virtually straight away. You can tighten them up, by squeezing them in with a pair of pliers.

So if you just had one of the team know the diameter of the stud using maybe the application and the sheet of metal that you are also using. We can determine the type of stud that's most ideal for your job. But in terms of the chucks, the collars, the arbors, we just need to know the diameter. So say, for example, here we've got Capacitor discharge (CD) M5 stud you're going to need an M5 Chuck. So each diameter stud has a matching chuck. The only time you need to change your arbour is when you change in the diameter of your stud.

An example of a chuck. You can see it's a lot wider. Give yourself 1 mil and tie it up. That goes straight into your hand tool and away you go. You ready to weld to make.

The CD collet, the chucks, the arbors, the mandarins are consumables. They do burn out. You must ensure that you replace them on a regular basis to ensure a good quality weld. If you want to learn more about it, there's other videos on our website, which is www.studfast-studwelding.com, where you can interact with us. Ask us any other questions you might have, and we'll be on to them straight away.

Some commons problems with chucks cd can be not securing the chuck nut in the gun. If you find, the chuck collet just keeps coming out of the gun then there is no power in the weld.

Some customers have got in touch with us to say the chuck collet looks like it is threaded inside. We will always send a free chuck nut key when you buy a new machine from Studfast Studwelding. In order to rectify this problem you will require a chuck securing key to tighten up the nut and this will secure your chuck and prevent it from falling out. The weld will not go through unless the chuck is secure as has to complete the connection.